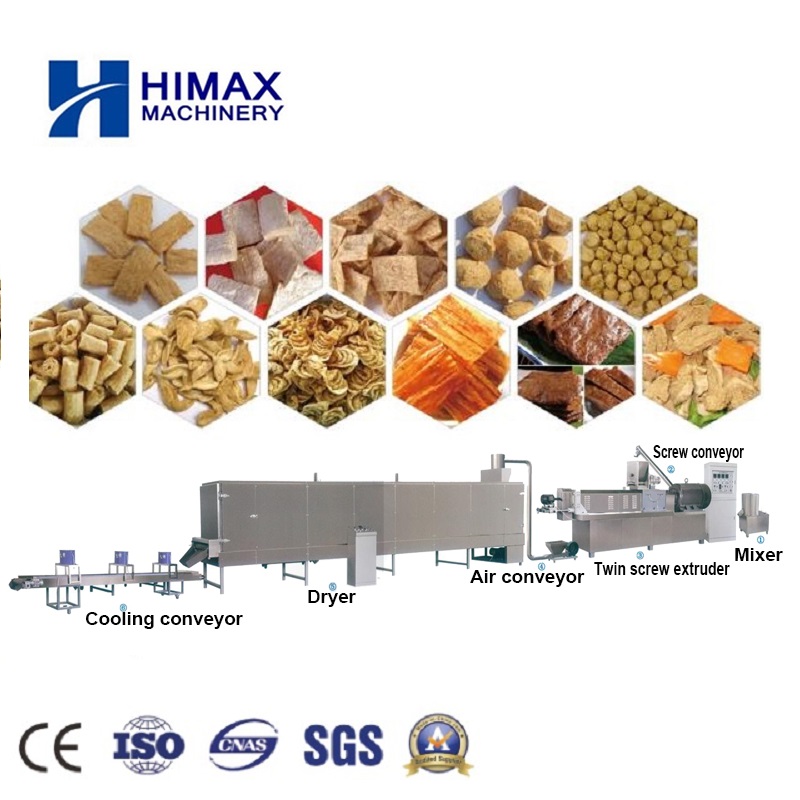

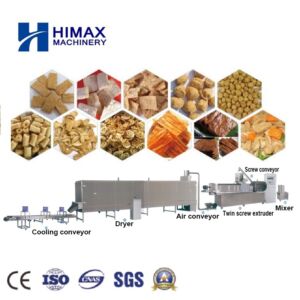

Textured Soy Protien Production Line

Textured Soy Protien Production Line uses soya bean powder or peanut powder to break spherical protein molecules to form chain protein molecules, thus creating slice-like fiber structure, by powder-grinding, stirring, high-temperature, high pressure and high-cutting.

Soy meat Making Machine is manufactured with our rich experiences in the food industry for over ten years. textured vegetarian soy protein machine uses nonfat soybean meal as the main material to produce all kinds of soybean protein food and vegetarian meat, which are nutritional and easily absorbed by the human body. The textured soy protein is like muscle and has a sense of mastication. Textured soybean protein is widely applied to many industries, such as can, seasoning, ham, meat, cooking, etc.

Application

Food additive for deep-fried food, and mainly for frying food surfaces, such as fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious, and nutritious.

Raw material

This line adopts low-temperature soybean meal, peanut meal, wheat gluten isolated soya, etc as main raw materials, which can produce textured protein and fiber protein with certain strength and toughness.

Corn, rice, wheat, oat, barley, millet, sorghum, etc as the main ingredients

Main Features of industrial nutritional Meat analogue Making Machine

1) Belt transmission between motor and gearbox, reducing energy consumption.

2) Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with a more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life. Segmental assembled screws are applied to more kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong life.

5) Double screws feed equal materials forcibly.

6) Hanging mold and knives seat and bearing knife adjusting system can adjust the knives exactly and swiftly.

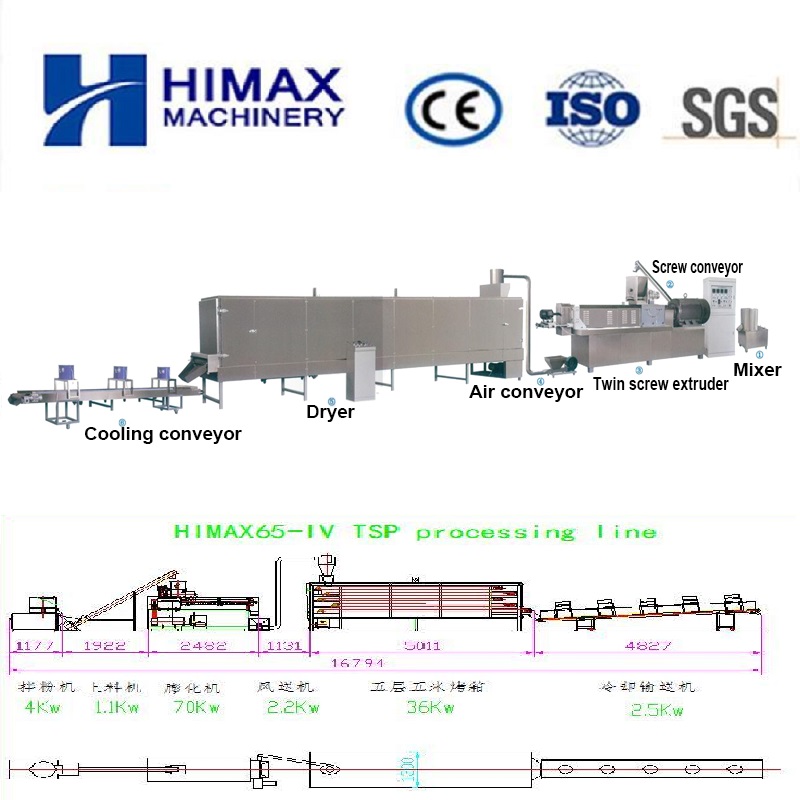

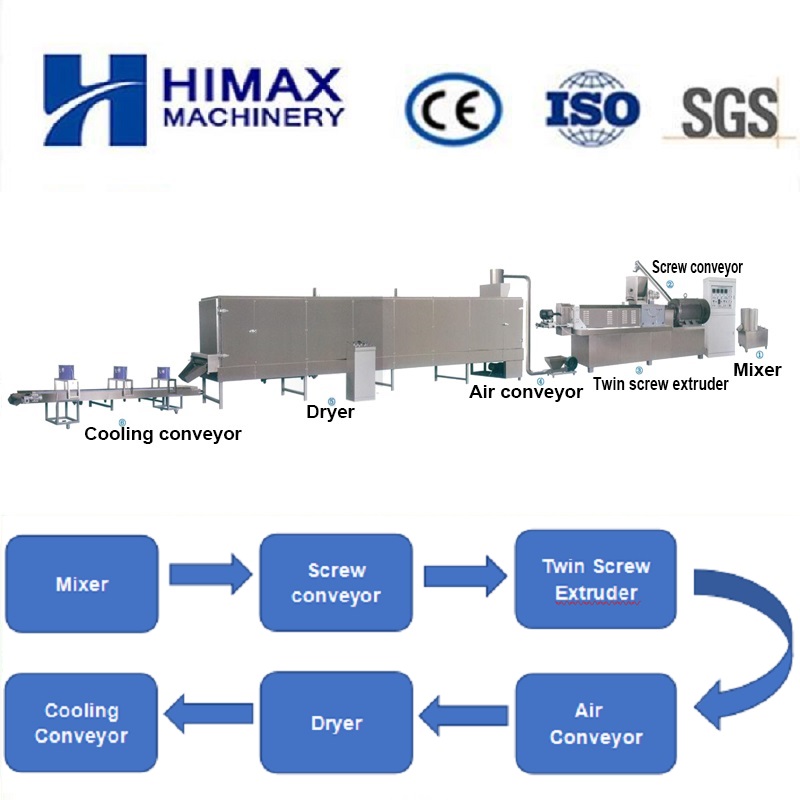

Flow chart

Grinding→mixing→extruding→drying→crusher→cooling→packaging

Technical Parameters

| Model | HM65 | HM85 |

| Installed power | 68.5kw | 165kw |

| Power consumption | 43kw | 103kw |

| Capacity | 240-280kh/h | 400-500kg/h |

| Dimension | 18000*1200*2200mm | 22000*3500*2300mm |

Specifications

WhatsApp NO:+86 151 6506 9582

Capacity:240-280kg/h, 400-500kg/h

Used for:making all kinds of soybean protein food and vegetarian meat.

Certification:CE ISO SGS.

Advantage:Environment-friendly,Energy-saving,High-efficiency,Steady quality,Customization service.

Energy Source:Electricity,Diesel Oil, Gas.

After-sales Service Provided:Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support