Kurkure Production Line

Product description

Cheetos Kurkure is a special extruded small food with a very crisp taste. Using corn ballast as the main raw material, after being mixed by a powder mixer, it is squeezed and kneaded by the rotary table of the extruder to form irregular twisted strips. According to customer requirements, it can be cut into products of different lengths. Finally, it is baked at high temperature. After roasting or deep-frying and seasoning, the corn noodles with rich flavor and crispy and delicious which are widely favored by consumers are produced.

Features

The Kurkure making machine is a special extrusion.The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the cheetos extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes. The cutting knives can cut into required lengths.After passing through the extruder, there are two cooking methods of frying and baking,they are fried in cooking oil or toasted in oven and then cooled before flavoring. Seasoning is sprayed on the surface to achieve different favorable tastes.

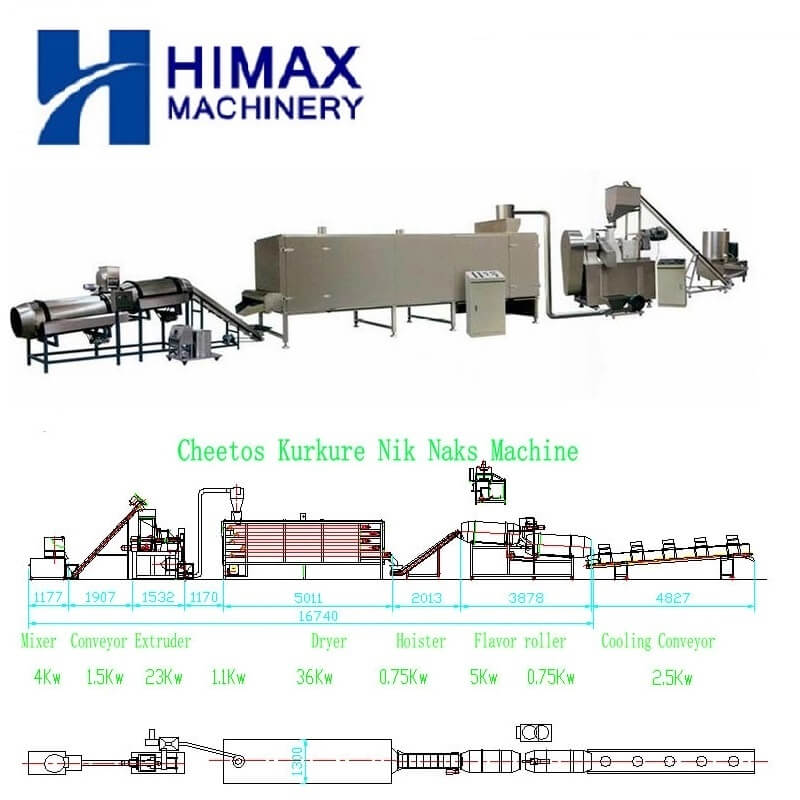

Flow chart

Mixer–screw conveyor– HM76 extruder –sifter –hoister –fryer –de-oil machine — flavoring Line — cooling machine–packing machine

HM76 cheetos curis/kurkures extruder

1. The corn stick production line is divided into two processes: frying and baking

2. The latest rubbing and squeezing technology makes the product crisp and delicious.

3. Exquisitely designed and precise control system.

4. The key parts are cast in brass, with good abrasion resistance.

5. Vibrating feeding makes the feeding even and adjustable.

Material characteristics

The main extruder uses a 15kw Siemens brand frequency conversion motor, the feeding system uses a 0.37kw vibrating motor, and uses Schneider Electric accessories.

All food-contact parts are made of food-grade 304 stainless steel.

Final product