Fried bugle chips production line

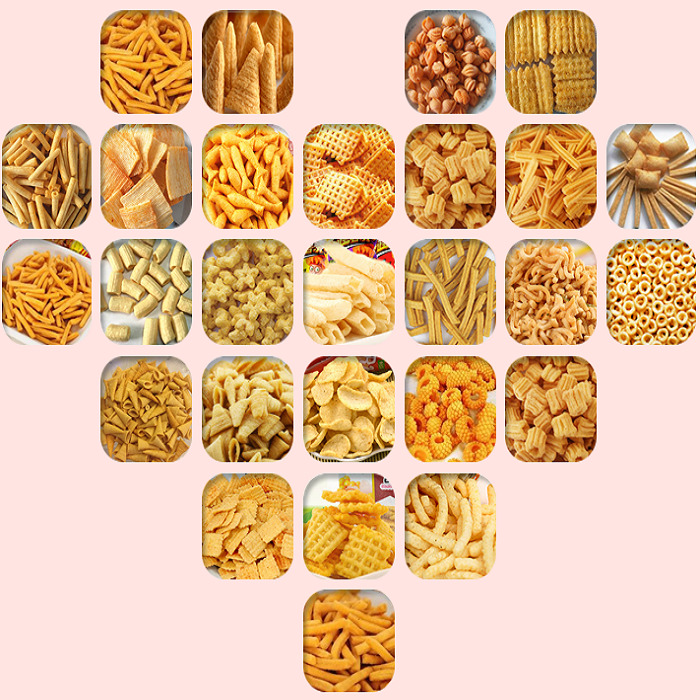

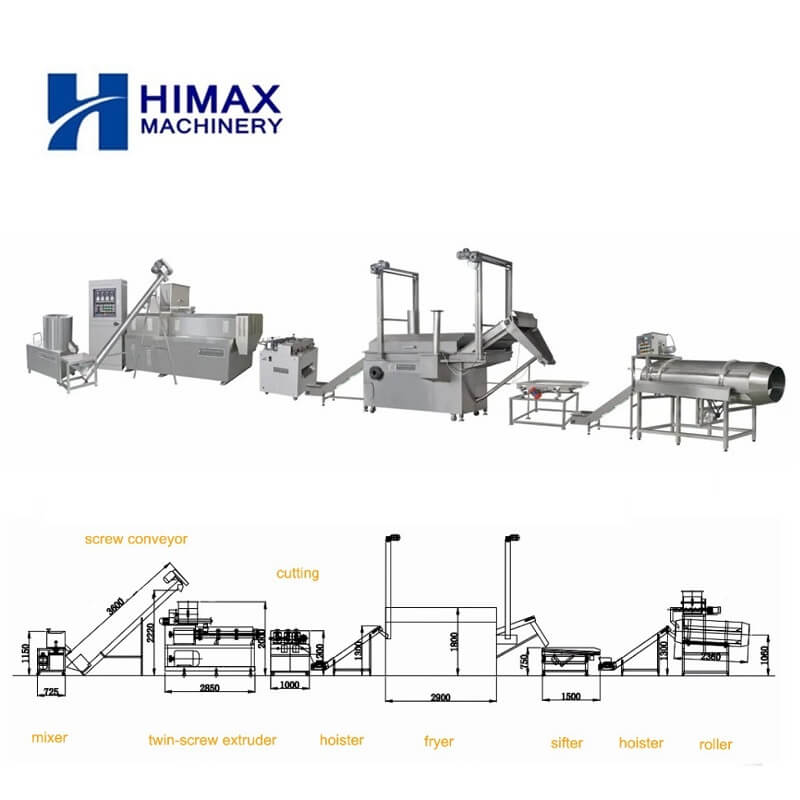

Fried snacks production line is a new technology that replaces the traditional production by twin-screw extrusion technology. The production line including mixing materials, Extruding and expanding, Forming in one, no need boiler, and the production process is simplified, efficient, environmentally friendly and low-carbon. Then forms a kind of leisure food after extruding,slaking,forming, drying, frying and flavoring. The shape can be changed by changing the mould and the forming machine and the cutting machine, such as strips, waved square sheets, diamond sheets, pillows, and triangles. The Crispy Rice, Salad Chips, and Bugles chips are all varied, and the taste is crisp and not greasy.

Fried snack pellet/fried chips/bugle/doritos/potato chips/rice crusts making machine can make all kinds fried snacks(such as rice crusts, chips, bugles, pizza rolls, doritos) based on changing die moulds and manufacturing technique. The production process includes mixing, extruding, cutting, frying, flavoring and packing. The products are crisp and less oil.

Its main ingredients are flour, cornmeal, water, vegetable oil and salt. After being fried, it is sprayed on the surface with seasoning powder of various flavors. The shape can be changed only by changing the mold and the forming machine fish cutting machine: sticks, square sheets rib chips, diamondchips, wavy chips, pillow-shaped and buhles, etc. The produced crispy rice, salad sticks, sharp corner crispy, wonderful crispy corners and other foods are diverse in color, crispy and not greasy.

Twin Screw Features

1.The main extruder adopts frequency speed controlling with high automation.

2.The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure,and longer life.

3.The forced lubrication system ,which can guarantee the equipment transmission life longer.

4.Auto-temperature control system and self-cleaning ,which makes it more convenient.

5.It has the widest range of applications and can produce different products with different equipment and models.

Fried bugle chips production line molds

Fried bugle chips production line flow chart

| Model | HM65 | HM70 | HM110 |

| Installed power | 89kw | 106kw | 120kw |

| Power consumption | 58kw | 68kw | 110kw |

| Csapacity | 120-150kg/h | 180-240kg/h | 400-500kg/h |

| Dimension | 19000*1500*2200mm | 20000-1500-2200mm | 25000-2300-2000mm |

Final product

Different fried foods can be customized by changing the mold