Twin Screw Fish Feed Extruder

Product description

Aquatic feed pellet making machine made by our twin screw extruder machine. Mainly use corn flour, fish powder, meat powder and some food additive as main raw material, through mixing, extruding, roasting, flavoring to get the final puffed Fish Feed food. By help of minerals, rich nutritional content and protein enrich fish growth life, ideal choice for factory. This line is fully automatic, high capacity and with different of shapes. It can produce such as cat food, dog food, fish food, bird food and so on.

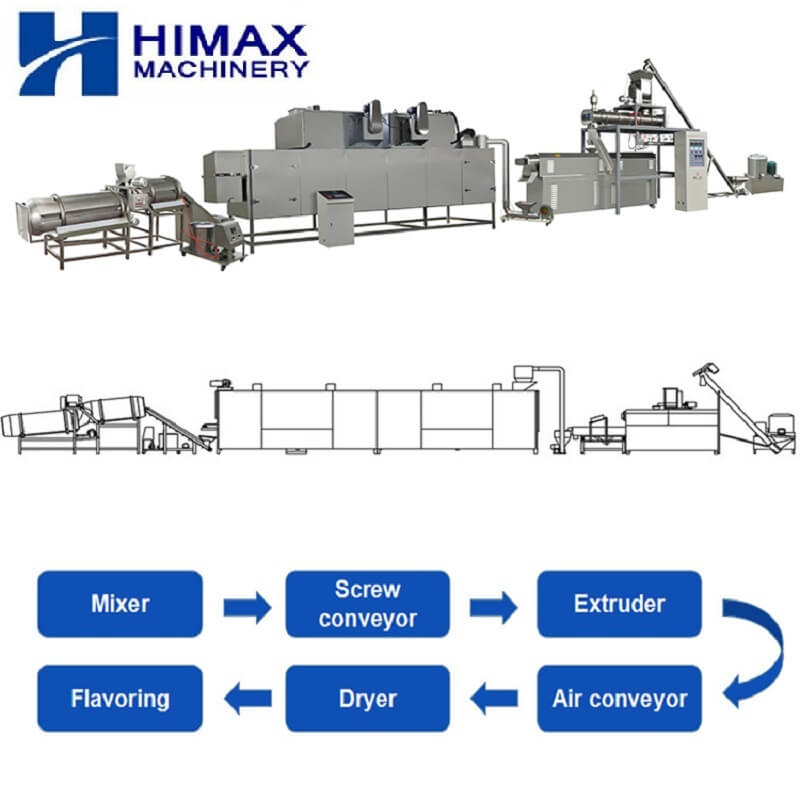

Flow Chart

Mixer–>Screw Conveyor –>Twin-screw extruder –>Air conveyor–>Dryer–>Hoister–>Flavoring machine–>Cooler

Technical Parameter

| Model | HM65 | HM70 | HM85 | HM90 | HM95 |

| Input Voltage | 380v/50hz | 380v/50hz | 380v/50hz | 380v/50hz | 380v/50hz |

| Installed power | 70kw | 90kw | 120kw | 96kw | 180kw |

| Power consumption | 40kw | 50kw | 100kw | 80kw | 120kw |

| Capacity | 120-150kg/h | 200-250kg/h | 400-500kg/h | 800-1000kg/h | 800-1000kg/h |

| Dimension | 2200*120*220cm | 2400*150*220cm | 2800*350*230cm | 3000*350*230cm | 4500*250*250cm |

Fish feed making machine details

Mixer: 304stainless steel material

1.Makes the raw material adding to water and liquid chemical additive fully mixed.

2.The discharge hole adopts the new handle-opened design. It has the good seal

Screw Conveyor

The mixed materials can be conveyed in the stainless steel roller to the feeding machine (feeder) of extruder without any leaking,

dusting and pollution; Feed quantity and speed is even and stable.

Twin Screw Extruder

The twin -screw extruder is made of the feeding system, extruding system, cutting system, heating system, conditioner and

controlling system.

1.The screws are made of the alloy steel;

2.The forced lubrication system ;

3.Auto-temperature control system.

Finished product