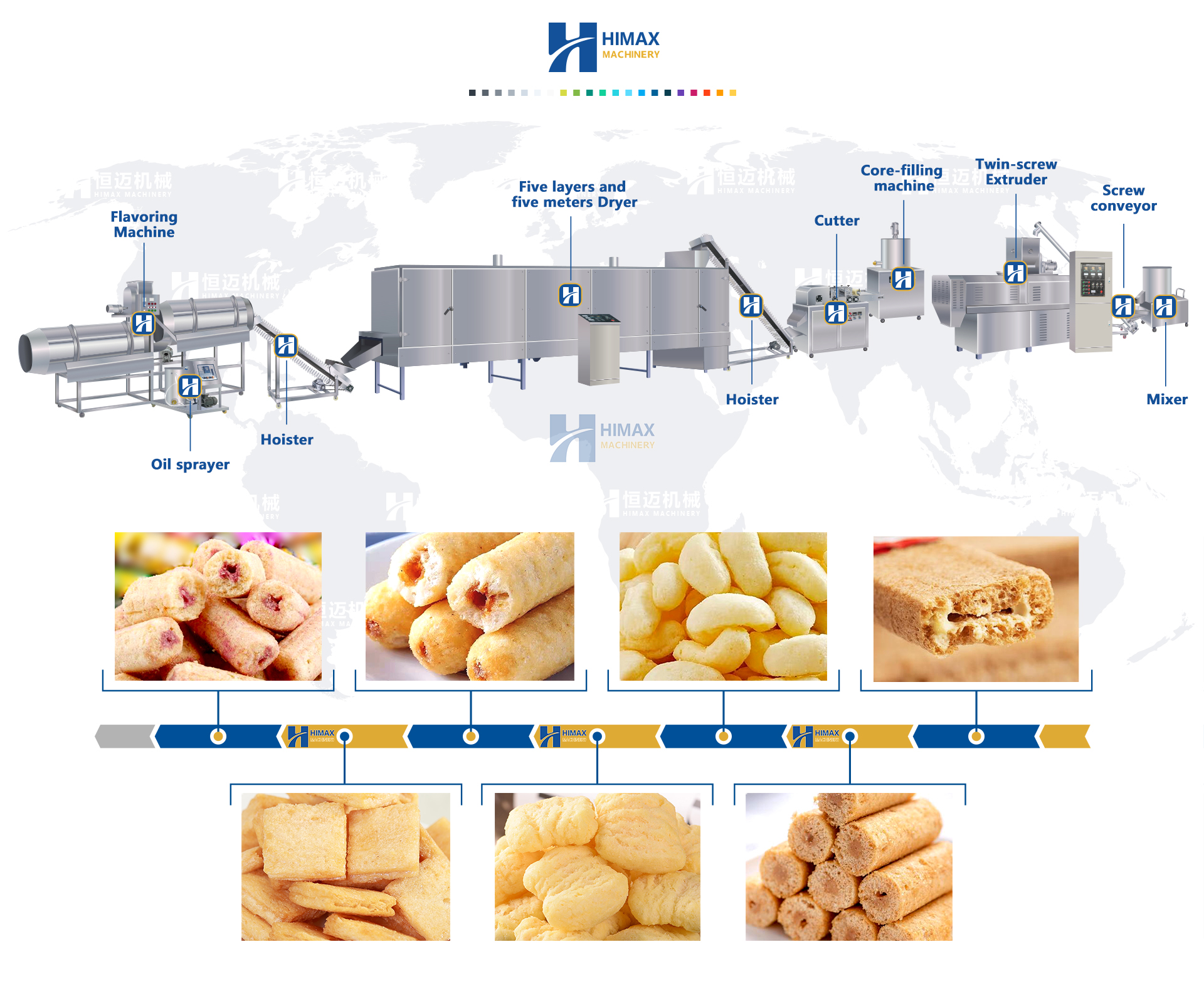

Corn Puffed Snacks Production Line Snack Cheese Balls Extruder Making Machine

The production line is complete from raw material preparation, extrusion and puffing, core filling, forming, cutting, spraying, seasoning to finished products at one time, with a high degree of automation. The production line has the characteristics of many optional models, flexible equipment configuration, wide range of raw materials, many types of products, and simple operation. Replace the mold and choose the appropriate production process to produce puffed food such as sandwich cake, siu mai, wheat-flavored chicken nuggets, nutritious breakfast, corn flakes, etc. The puffed food has the characteristics of crisp taste, easy digestion and unique fragrance, and is an ideal snack food for consumers.

The Puffed Snacks Production Line is complete from raw material preparation, extrusion and puffing, core filling, forming, cutting, spraying, seasoning to finished products at one time, with a high degree of automation. The production line has the characteristics of many optional models, flexible equipment configuration, wide range of raw materials, many types of products, and simple operation. Replace the mold and choose the appropriate production process to produce puffed food such as sandwich cake, siu mai, wheat-flavored chicken nuggets, nutritious breakfast, corn flakes, etc. The puffed food has the characteristics of crisp taste, easy digestion and unique fragrance,and is an ideal snack food for consumers.

Process flow

Raw material mixing–transportation–expansion molding–baking–seasoning-baking–cooling packaging

Device Configuration

Flour Mixing Machine –screw conveyor–twin-screw extruder–multilayer oven–seasoning line–single layer oven–cooling conveyor–packaging Machine

Technical parameters

| Model | HM65 | HM70 | HM85 |

| Installed power | 74kw | 105kw | 150kw |

| Power consumption | 55kw | 75kw | 150kw |

| Csapacity | 100-150kg/h | 180-240kg/h | 400-500kg/h |

| Dimension | 17000*1300*2200mm | 20000-1500-2200mm | 30000-1500-2600mm |

Product Features

1.Feeding, rotary cutting, and main drive all adopt frequency conversion speed regulation system, which has strong power, stable operation and energy saving.

2.The screw is made of alloy material through special technology, and has a long service life; the segmented combined screw is suitable for a wide range of raw materials and more diverse products.

3.Automatic lubrication system reduces mechanical energy consumption and prolongs service life.

4.The feeding system adopts double-screw forced feeding, and the feeding is uniform and wide

5.Linear bearing tool adjustment system, accurate and fast tool adjustment.

6.The twin-screw has a self-cleaning function, making the use of equipment more reasonable and convenient

Advantage

· The Puffed Sncaks Production Line is stainless steel.

· Puffed Snacks Production Line is fully continuous and automatic.

· The final shapes and sizes can be varied by changing the molds.

· Free formula and molds are provided.

· Packing machine is supplied to work with puffed snacks food making machine on your requirements.

Final product