Instant noodles Production Line

Product description

Instant noodle making machine production line realizes synchronous coordinated control, digital display of cutting frequency, automatic control of frying temperature, simple and safe operation, convenient maintenance, and highly qualified product rate.

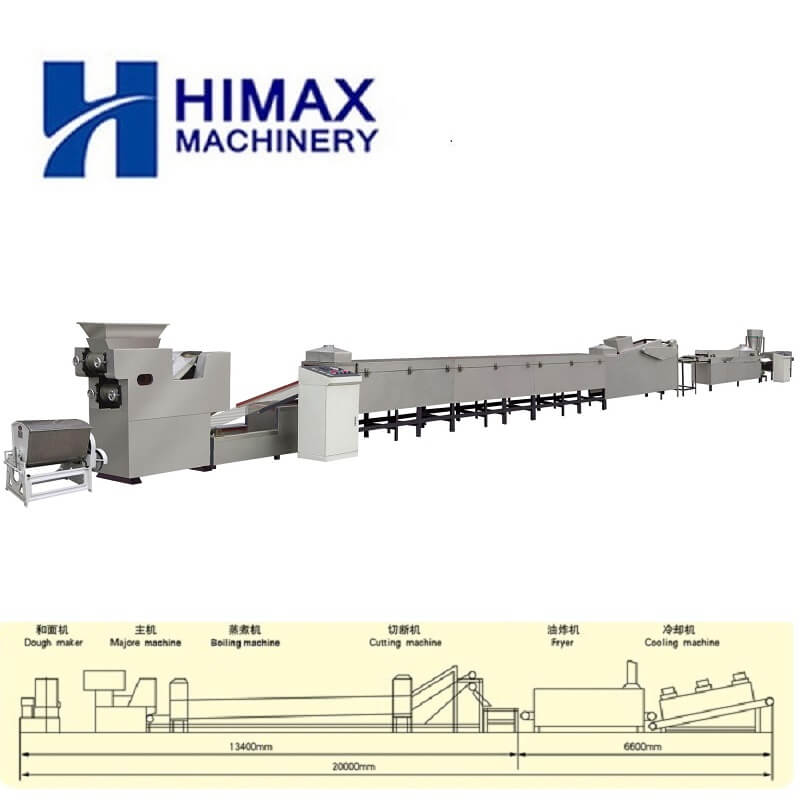

Instant Noodle Production Line consisted of dough maker, roller pressing machine, steam noodle machine, cutting machine, frying machine, and cooler. It is on the basis of the research of similar products at home and abroad, combined with the needs of the mass consumer market.

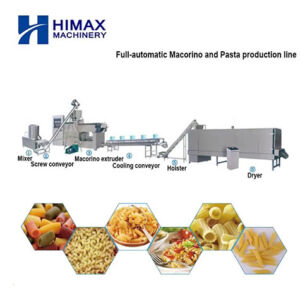

Its main raw material is wheat flour.Instant Noodle Processing Line is widely used to make rice, wheat, and other kinds of noodles. It can make different shape noodle by changing the molds.

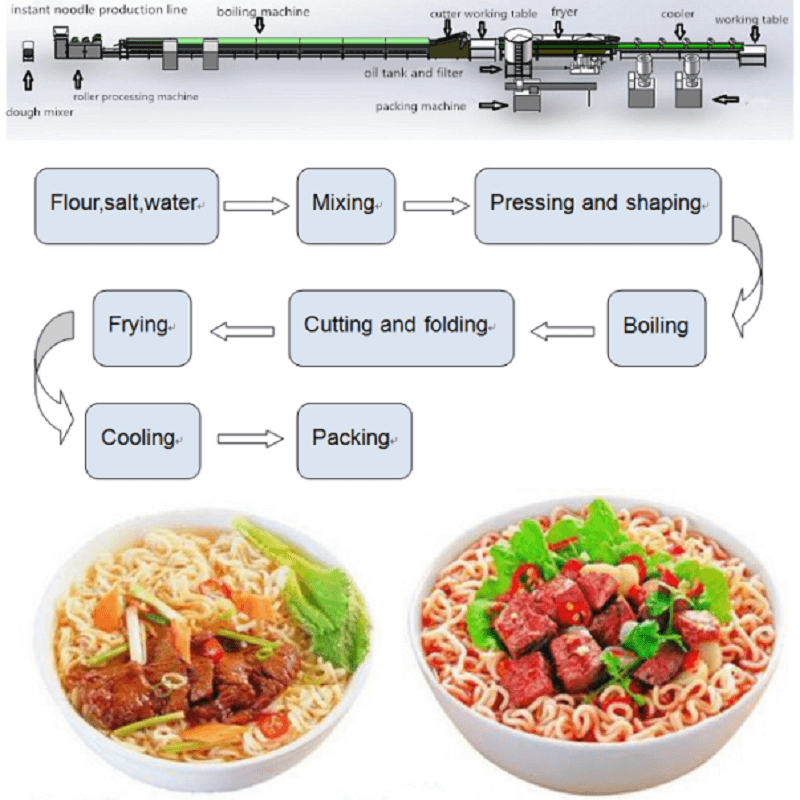

Processing flow

Flour mixing –dough curing– composite rolling — noodle steaming — cutting — frying&drying — air cooling — packaging

Feature

1.The size of instant noodles can be adjusted easily .

2.pressing & shapping machine , cutting machine and frying machine are all frequency control .

3.Rolling pressing design make the noodles springy .

4.Adopt good quality and food-grade stainless steel , which is longer service life and neatness .

5.Longer frying length to ensure good cooking and better taste of instant noodles .

6.Cooling conveyor is special designed with oil filtering function .

7.High automation and accurate control systerm to save labor cost and improve the quality of final products .

Final product

Specifications

WhatsApp NO:+86 151 6506 9582

Capacity:100-150kg/h, 200-260kg/h, 400-500kg/h

Used for:producing many kinds of noodles, such as square and round.

Certification:CE ISO SGS.

Advantage:Environment-friendly,Energy-saving,High-efficiency,Steady quality,Customization service.

Energy Source:Electricity,Diesel Oil, Gas.

After-sales Service Provided:Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support