Factory Direct Sales Competitive Price Fish Feed Machine

Fish feed extruder machine is widely used in the production of dog, cat, fish, shrimp, poultry, livestock, breeding, bird and various pet feeds. It is an ideal choice for different manufacturers.Fish food processing equipment can adjust the raw materials, temperature, moisture and other process parameters, so that the product has the characteristics of novel shape, texture, rich nutrition, and delicate organization, which is suitable for the use of different fish.

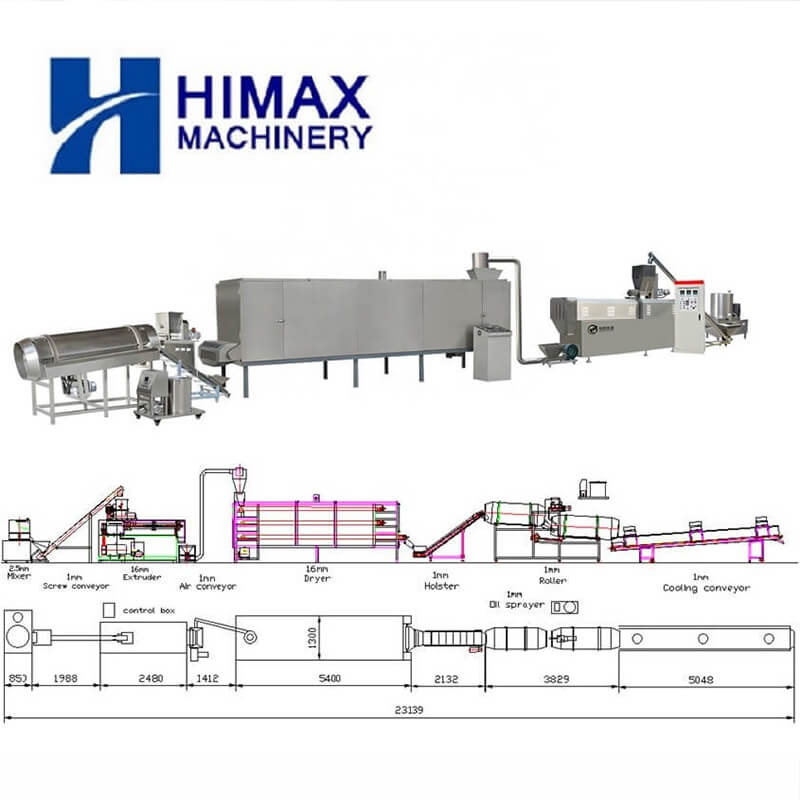

Production Process

Feeder → Pulverizer series group → Buffer bin → Screw feeder → Ribbon mixer → Bucket elevator → Twin screw extruder → Air conveyor → Steam dryer or electric heating dryer or hot air dryer → Air conveyor → Counterflow cooler → Vertical oil mixer → Vibrating screen bucket → Elevator → Food packaging machine

Features

1. Fish feed manufacturing machine can be matured and expanded to gelatinize the starch and destroy the harmful components in the protein raw materials, improve the digestibility of the feed, and reduce the feed coefficient.

2. The maturation process can be sterilized, reducing the stress and disease rate of the fish, and increasing the output of the fish.

3. The feed has high stability in the water, it will not disperse or sink for 24 hours, and it will be all eaten by fish, which improves the utilization rate of feed.

4. It does not pollute the water quality and achieves the purpose of maintaining fish in the ring.

5. Floating water feed is convenient for observing the feeding of fish, adjusting the amount of feed, and improving the utilization rate of feed.

Technical parameters

| Model | HM65 | HM70 | HM85 | HM95 |

| Input voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Inatalled power | 70kw | 90kw | 120kw | 180kw |

| Power consumption | 40kw | 50kw | 100kw | 120kw |

| Capacity | 120-150kg/h | 200-250kg/h | 400-500kg/h | 800-1000kg/h |

Final product