Dry Pet Food Production Line Dog Cat Food Extruder Making Machine

The Himax pet food production line uses twin-screw extrusion technology, which uses high temperature and high pressure to simultaneously shape the material.Raw materials, temperature, humidity and other parameters can be adjusted so that the resulting products are bright in color, diverse in assortment, beautiful in appearance and delicate in texture, which are suitable for the tastes of various pets.And it adapts to the emerging pet food market, with the characteristics of easy digestion and nutritional value.

The pet dog extruder making machine has characteristics such as new design, high performance and stable operation.The main components of the equipment are made of special alloyed materials and according to special technological processes, which have the characteristics of high wear resistance and long service life.This pet food production line solves disadvantages such as the insufficient degree of swelling of a small single screw machine, the difficulty of cleaning the screw after production, the limited ratio of adding fresh meat and bone powder, fast screw wear and high cost of accessories, customers like it.

Raw materials

Corn meal, fish meal, meat meal, protein food, soybean, etc. This floating fish feed production line can produce pet feed, fish feed, shrimp feed and other marine biological feed.

Dog food making machine capacity:100~200kg/h, 200~260 kg/h, 300~500kg/h, 600~800 kg/h, 800-1000kg/h, 1000-2000kg/h, 3ton—6ton/h, etc

Pet food production line application

Dog food, cat food, kibbles, pet feed, animal feed making machine equipments.

Pet food extruder machines materials

All the machines are made by stainless steel food grade.

Pet food making machine technical parameters

| Model | HM65 | HM65 | HM85 | HM90 |

| Installed Power | 70KW | 90KW | 120KW | 170KW |

| Power Consumption | 22KW | 45KW | 45KW | 90KW |

| Production Capacity | 100-150Kg/h | 200-260Kg/h | 600-800Kg/h | 800-1000KG/H

|

| Production Capacity | 24000*1500*2200mm | 30000*3500*2300mm | 35000*3500*2300mm | 35000*3500*2300mm |

Different shapes and sizes of feed can replace molds and adjust the degree of expansion.

Dog food shapes: heart, bone, circle, triangle, small fish shape, square, etc.

Cat food shape: heart, bone, circle, triangle, small fish shape, square, etc.

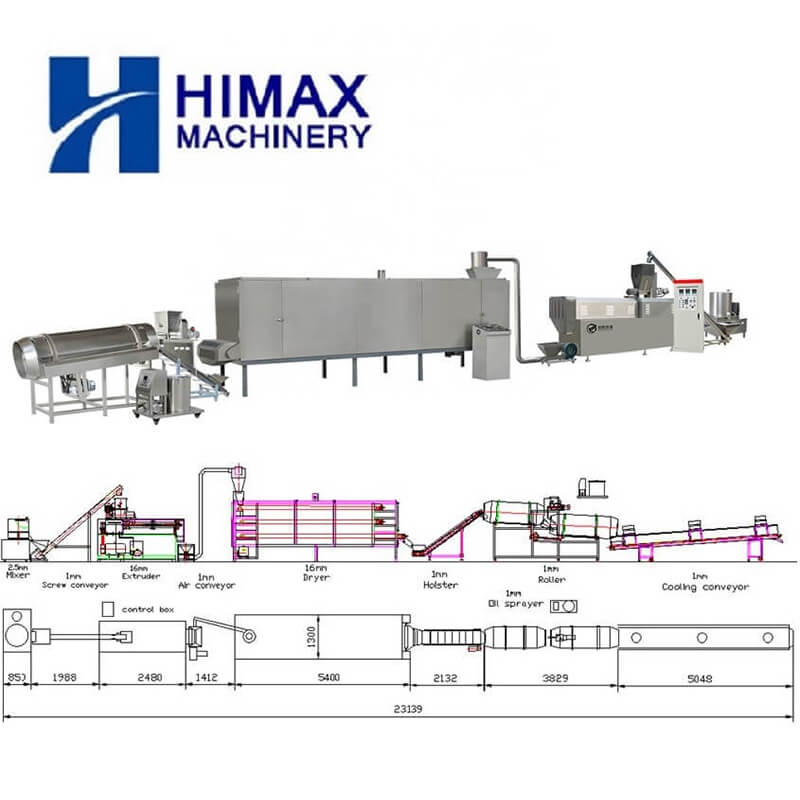

Pet food production line production process

Mixer— Screw conveyor— Twin-screw extruder —Hoister — Dryer —Flavoring line—Cooling

1)Receiving and initial cleaning of raw materials: use cylinder primary cleaning sieve and permanent magnetic cylinder to screen raw materials and remove impurities;

2)Grinding stage: use a feed mechanical grinder to grind the material to a suitable particle size;

3)Mixing stage: The mixing equipment mixes the materials in a certain proportion.

4)Extrusion and puffing stage: use twin-screw extruder equipment to extrude the material into the desired shape;

5)Cooling stage: Cool the high-temperature pellet feed with cooling equipment such as a counter-flow cooler;

6)Crushing stage: use a crusher to break the pellet feed into a suitable size;

7)Screening stage: Use rotary grading sieve and other screening equipment to screen out the finished feed that meets the standards;

8)Packaging stage: Quantitative packaging of the pellet feed with a packaging scale.

Finished product

The pet dog food production line is widely used in the production of various pet foods such as dogs, cats, fish and shrimp, foxes, etc., and is an ideal choice for various manufacturers.Jinan Himax Machinery Co., Ltd. provides a complete set of service systems, including optimized plant layout design, thoughtful formulation, installation and commissioning, as well as after-sales service.