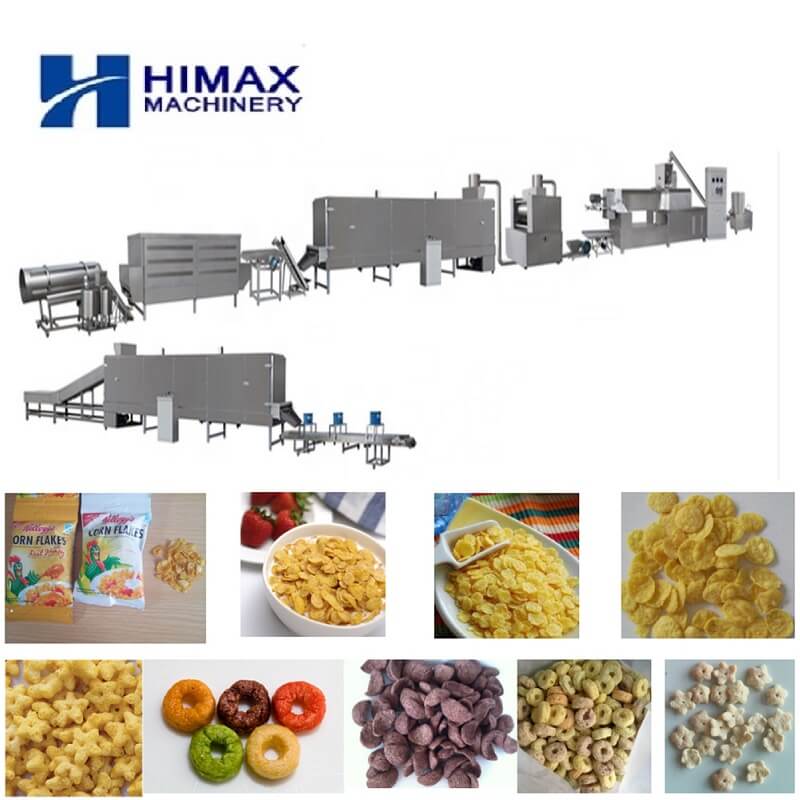

Corn Flakes Production Line

Product description

Corn flakes are rich in nutrients and relatively balanced. They are cereal breakfast foods and are usually eaten with milk.Corn Flakes Breakfast Cereal Snack Food Extruder Production Line has the characteristics of multiple models, flexible equipment configuration, wide range of raw materials, multiple product types, and simple operation. By changing different molds and changing the production process, various puffed foods popular on the market can be produced, which is suitable for various food manufacturers.

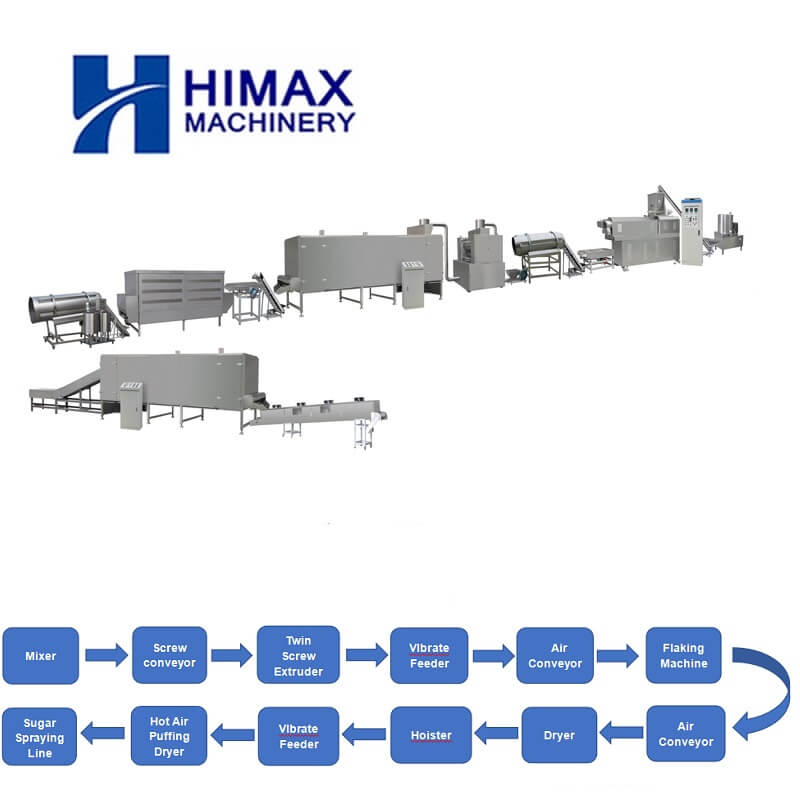

Flow Chart

Mixer–screw conveyor–twin screw extruder–sifter–air conveyor–flaking machine–hoister–drye–hoister–high temperature oven–hoister–double roller flavoring line–climbing machine–cooling machine–packing machine

Twin screw extrude

The twin screw extruder is made of the feeding system, extruding system, cutting system, heating system, transmission system and controlling system.

1.The screws and barrel are made of the alloy steel;

2.The forced lubrication system ;

3.Auto-temperature control system and auto-speed control system

4.Self-cleaning function.

5.Using Siemens brand frequency conversion motor,Schneider Electric

accessories,Delta inverter and NSK bearing

6.Automatic lubricating and forced cooling make sure that extruder performs safely and extends using life.

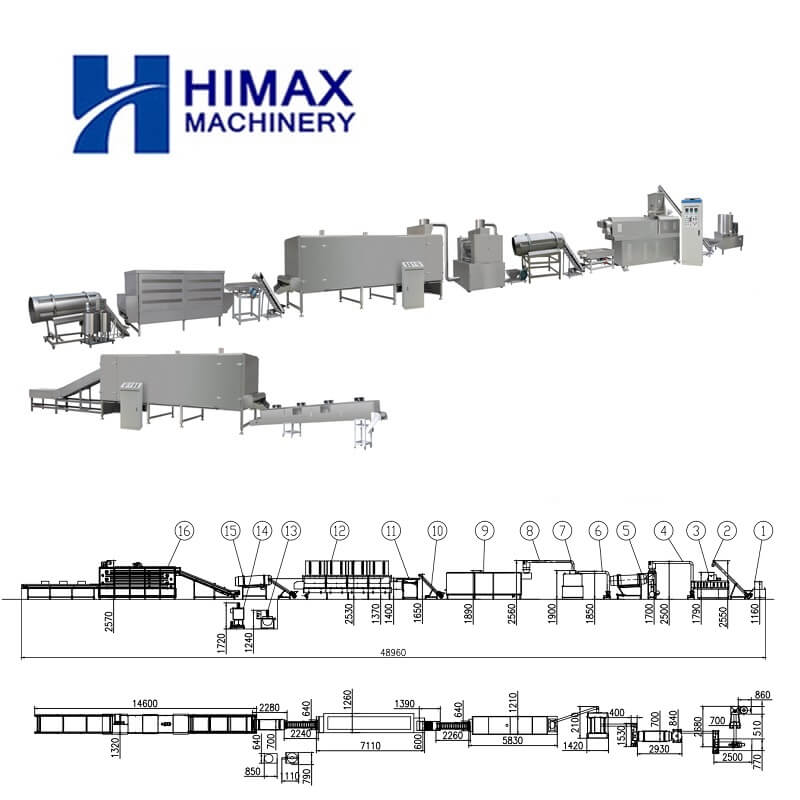

Technical parameters

| Model | Capacity | Dimensiom | Main motor power |

| HM70 | 200-260kg/h | 41000*1500*2200mm | 55kw |

| HM85 | 300-500kg/h | 52000*2200*2800mm | 75kw |

| HM90 | 800-1000kg/h | 56200*3500*4300mm | 90kw |

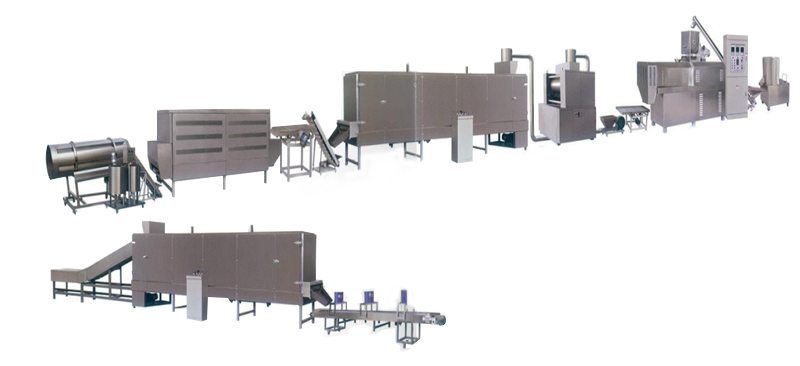

Production line advantages

1.Flaking machine is equipped with water cooling system.

2.Equipped with a permanent magnet cylinder, it can absorb impurities such as iron filings in raw materials to ensure product quality.

3.The oven has a variety of energy options and can be selected as single electric, gas, steam or diesel heating. Can also be selected for mixed energy heating, such as electricity and gas or electricity and steam.

4.The configuration of the high-temperature oven can make the surface of the cornflakes baked with air bubbles, making the taste more crispy. In addition, it is easier to soften when soaked in liquids such as milk.

5.All parts in contact with the machine are made of food-grade stainless steel 304.

Final product