Bread crumbs Production Line

Product description

Panko bread crumbs making machine produces bread crumbs which are food additives for deep-fried food, and mainly for frying food surfaces, such as fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc.

Bread Crumb is mainly used for Fried Beefsteak and chicken as frying dressing. This line is specially designed and developed to operate from the material to final shaping automatically with less manpower, without waste, lower production cost, and higher production efficiency. This process line is firstly designed and manufactured by our company.

Application

Food additive for deep-fried food, and mainly for frying food surface, such as fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious, and nutritious.

Raw material

For bread crumbs production. It is from powder for wheat flour to bread crumbs automatically. No bread was produced during the whole process. So no bread crust appeared. The final product is bright white and with good texture.

Corn, rice, wheat, oat, barley, millet, sorghum, etc as the main ingredients.

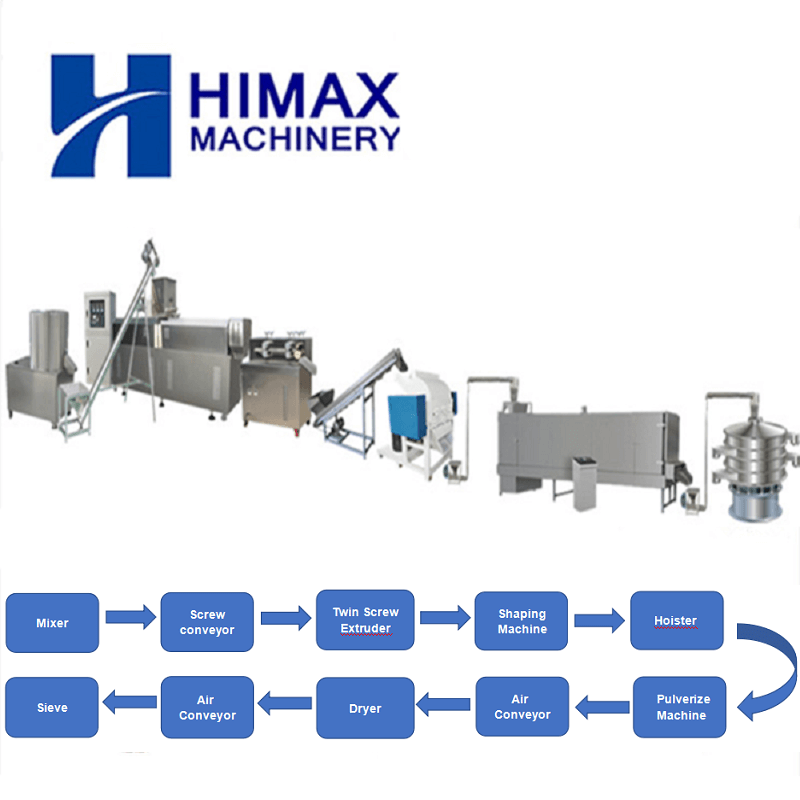

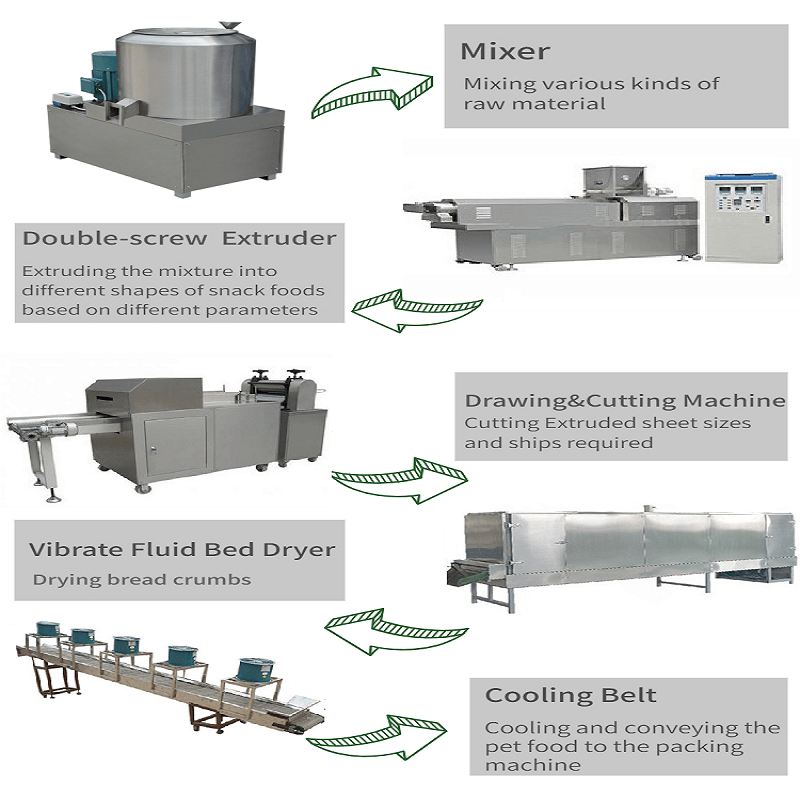

Flow chart

Grinding–mixing–extruding–drying–crusher–cooling–packaging

Technical parameters

| Model | HM65 | HM70 |

| Installed power | 81.37kw | 104.37kw |

| Power consumption | 61kw | 78kw |

| Csapacity | 100-150kg/h | 200-260kg/h |

| Dimension | 18000*1300*2200mm | 30000-1300-2200mm |

Features

1.Belt transmission between motor and gearbox, reducing energy consumption.

2.Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with a more powerful drive, stable running, and low consumption.

3.Screw is made of alloy steel with long life. Segmental assembled screws are applied to more kinds of materials and products

4. Automatic lubrication system can lower down power consumption and prolong life.

5.Double screws feed equal materials forcibly.

6. Hanging mold and knives seat and bearing knife adjusting system can adjust the knives exactly and swiftly.

Final product