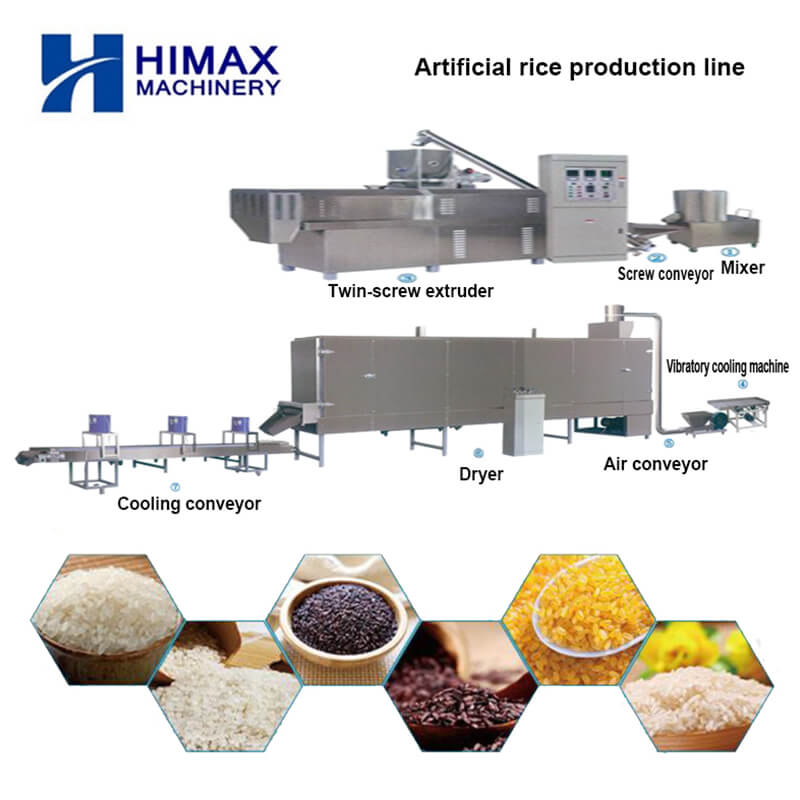

Artificial Nutrition Rice Production Line

Product description

Artificial rice production line adopts the broken rice, corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient, and some other vitamins and minerals as part of ingredient. The material is extruded into rice shape by the twin-screw extruder and dried in a dryer to the needed moisture content. This artificial rice can be mixed with natural rice prior to cooking as usual. An artificial rice production line makes it possible to strengthen and solidify the micronutrient in the rice. When cooking is finished, its grains are not broken and there is no difference between the artificial rice and the natural one in viscosity, elasticity, and taste.

Raw materials

Main raw material is rice flour; also can mix corn flour, wheat flour, soya bean meal, meat meal, bone meal, vegetable fiber, etc.

Flow chart

Mixer–Screw conveyor–Twin-screw extruder–cooling machine–Air conveyor–Dryer–Cooling conveyor

Technical parameters

| Model | HM70 | HM85 |

| Installed power | 96.5kw | 165kw |

| Power consumption | 60.5kw | 103kw |

| Csapacity | 180-240kg/h | 300-400kg/h |

| Dimension | 20000*1500*2200mm | 22000-3500-2300mm |

Final product

Specifications

WhatsApp NO:+86 151 6506 9582

Capacity:100-150kg/h, 200-260kg/h

Used for:making various Artificial Rice, Nutritional Rice, Instant Rice, fortified rice, China man-made rice

Certification:CE ISO SGS.

Advantage:Environment-friendly,Energy-saving,High-efficiency,Steady quality,Customization service.

Energy Source:Electricity,Diesel Oil, Gas.

After-sales Service Provided:Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support